-

Home > Products > Glass Insulator

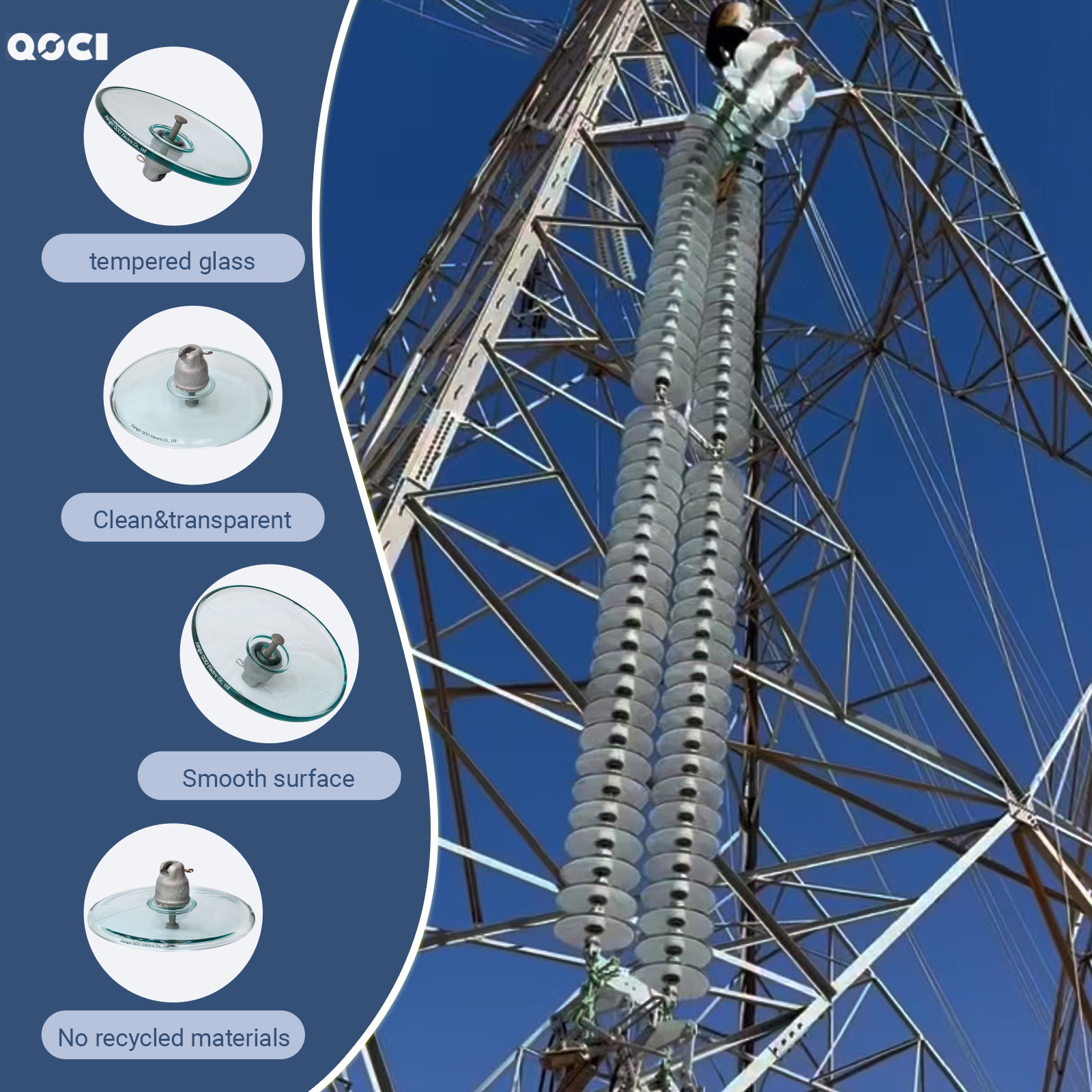

Glass Insulator U210AD With Zinc Bushing

The Aerodynamic Glass Insulator features a unique streamlined shed design to combat harsh wind and rain. It effectively prevents the formation of continuous water films, significantly increasing contamination flashover voltage for superior grid reliability in adverse conditions.

- Diameter: 420mm

- Height: 146mm

- Creepage distance: 380mm

Product Information

Model:U210BSA/U210AD

U Refers To Disc Suspension Insulator

210 indicates a rated Mechanical failing load of 210kN

B For Ball And Socket Type

S Stands For Short Steel Foot

L Stands For Long Steel Foot

AD Aerodynamic design

146/155- indicates that the height of the insulator structure is 146mm, and there are also insulators with spacing of 155mm.

420- indicates that the diameter of the insulator disc is 420mm.

380- indicates that the creepage distance of the insulator is 380mm.

Type: Open profile Toughened Suspension Type

Rated mechanical load: 210kn (about 21 tons)

Purpose: Aerodynamic glass insulators are primarily used in high-voltage transmission lines. Their Aerodynamic design resists strong winds, reduces vibration, prevents ice buildup, and enhances self-cleaning capabilities. They are ideal for harsh weather conditions (e.g., windy or frigid regions), ensuring line stability and safety.

The product model is in accordance with IEC60383-1:1993,MOD / GB/T1001.1

The connection structure is in accordance with GB/T4056-2008(IEC60120:1984,MOD) and BS 3288 part lll.

According to customer requirements, the locking pin can be either W-pin or R-pin.

lf there is no special instruction, R pin is used for U210AD

Product parameters

| IEC designation | Mechanical failing load | Nominal Diameter D | Nominal Spacing P | Creepage distance L | Socket coupling | Wet power frequency withstand voltage | Dry lightning impulse withstand voltage | Power frequency puncture voltage | Net weight |

| kn | mm | mm | mm | mm | kv | kv | kv | kg | |

| U70BSA | 70 | 380 | 127 | 365 | 16 | 45 | 90 | 130 | 5.2 |

| U70BLA | 70 | 380 | 146 | 365 | 16 | 45 | 90 | 130 | 5.3 |

| U100BSA | 100 | 380 | 127 | 365 | 16 | 45 | 90 | 130 | 5.2 |

| U100BLA | 100 | 380 | 146 | 365 | 16 | 45 | 90 | 130 | 5.3 |

| U120BSA | 120 | 380 | 127 | 365 | 16 | 45 | 90 | 130 | 5.2 |

| U120BLA | 120 | 380 | 146 | 365 | 16 | 45 | 90 | 130 | 5.3 |

| U160BSA | 160 | 420 | 146 | 380 | 20 | 50 | 95 | 130 | 7.2 |

| U160BMA | 160 | 420 | 155 | 380 | 20 | 50 | 95 | 130 | 7.3 |

| U210AD | 210 | 420 | 170 | 380 | 20 | 50 | 95 | 130 | 7.3 |

| U240AD | 240 | 420 | 170 | 380 | 20/24 | 50 | 95 | 130 | 7.5 |

| U300AD | 300 | 420 | 195 | 465 | 28 | 50 | 95 | 130 | 12 |

| Power frequency electric arc voltage:0.12s/20ka | |||||||||

| Impulse puncture voltage:2.8 P.U | |||||||||

| Corona visual test :18P/22C kV | |||||||||

| Radio interference voltage(10kV 1MHz):50μv | |||||||||

Suspension insulator components

Suspension insulators consist of the following elements:

- One dielectric made of toughened glass with the appropriate properties and shape for the environmental conditions in which it must function.

- One hot-dip galvanized nodular or ductile malleable cast iron cap.

- One hot-dip galvanized forged steel pin.

- The cap and pin are assembled on the glass piece using aluminous cement with the appropriate properties to withstand the thermomechanical efforts.

Lastly, the insulator cap has a stainless steel or phosphor bronze locking device (split pin) which secures the coupling of the units.

Similarly, the pins may be protected using an anti-corrosion zinc sleeve (sacrificial anode), when requested. This zinc sleeve is strongly recommended for insulators which are going to be used in lines with heavy pollution.

Detailed Photos

Packaging Method

Application Scenarios