-

Home > News > Industry News

Performance analysis of high‑voltage glass disc insulators in clean and polluted environments

Performance analysis of high‑voltage glass disc insulators in clean and polluted environments

High‑voltage glass power line insulators are critical components that keep overhead transmission and distribution lines electrically safe and mechanically secure. Their performance under clean and polluted conditions is usually evaluated using flashover and withstand voltage tests supported by finite element analysis (FEA) of the electric field distribution.

In this article, we focus on glass suspension insulators with different disc profiles and examine how design, material and testing influence insulation performance in real power‑system environments. The goal is to give engineers and technical buyers a clear, professional overview of how to specify and optimize glass electrical insulators, rather than to discuss antique or collectible insulators.

1. What is a glass power line insulator?

A glass power line insulator is an element designed to support and insulate high‑voltage conductors in transmission and distribution systems. It is typically made of toughened (tempered) glass discs assembled into strings, connected with hot‑dip galvanized steel caps and pins using high‑strength cement or resin.

Main characteristics of a modern glass electrical insulator include:

High dielectric strength and volume resistivity, which prevent current flow from live conductors to earthed structures.

High mechanical tensile strength, generally from 40 kN up to 300 kN for long‑span and UHV applications.

Resistance to weathering, UV, temperature cycling and mechanical fatigue.

A smooth, hard surface that resists pollution build‑up and is easy to inspect visually.

Because the glass disc is fully toughened, if it breaks it tends to shatter into small pieces while the metal fittings stay locked together, which is considered a fail‑safe or “self‑destruction” feature in many designs.

2. Is glass a conductor or an insulator?

From an electrical engineering perspective, glass is a very good insulator, not a conductor. Its high resistivity and high dielectric strength allow it to withstand significant electric fields without internal breakdown or significant leakage current.

Therefore, for questions such as “is glass a conductor or insulator” or “is glass a conductor or insulator of electricity,” the correct answer in power‑system applications is that glass is an insulator material used extensively in glass electrical insulators and bushings. This is why glass insulators are used for high‑voltage overhead lines, substations and other critical installations.

3. What are glass insulators used for?

Glass insulators used for high‑voltage systems provide both mechanical support and electrical isolation. In modern power networks, Glass Insulators are used for:

Overhead transmission lines (e.g., 110 kV, 220 kV, 400 kV, 500 kV and above), using glass suspension insulator strings.

Medium‑voltage and high‑voltage distribution lines with shorter strings.

Substation busbar support and equipment connections in post insulator transmission line configurations.

Railway electrification systems and catenary, where robust insulators on power lines are required.

Harsh environments such as coastal, desert or industrial areas, using anti‑pollution or aerodynamic profiles.

In every case, the glass power line insulator prevents dangerous leakage currents and flashovers that could cause outages, equipment damage or safety hazards.

4. Types of high‑voltage glass insulators and profiles

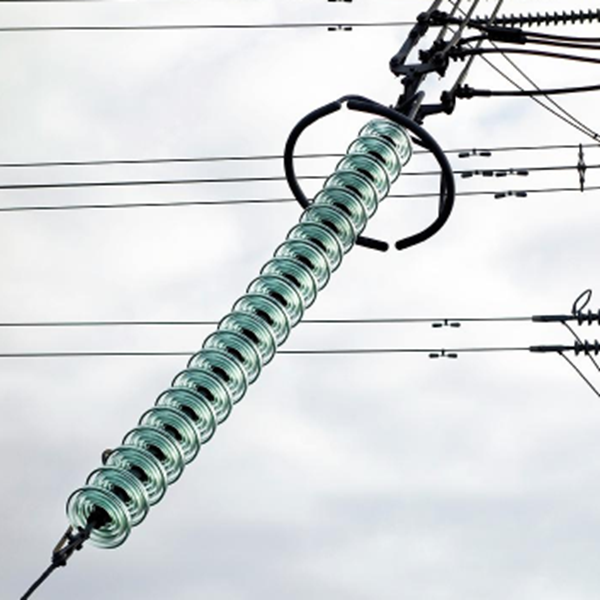

4.1 Suspension disc insulators

The most common glass insulator in transmission lines is the glass suspension insulator disc, assembled in series strings. Each disc is designed for a certain mechanical failing load and electrical rating, and multiple discs are used to reach the required line voltage and safety margin.

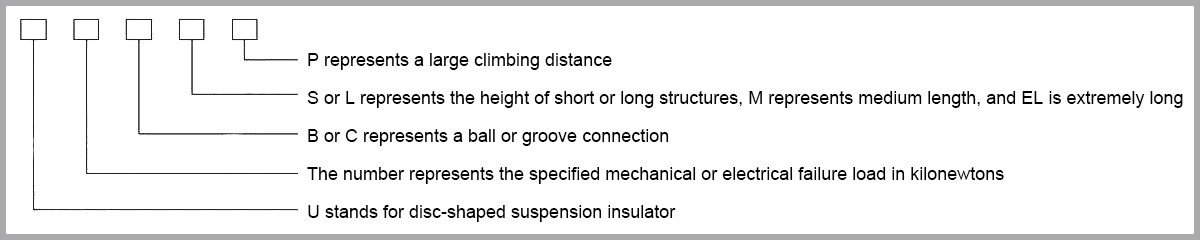

Typical product series include standard models such as U120, U160 and U300 types, with working voltages from 10 kV up to 500 kV and mechanical strengths from 40 kN up to 300 kN. Disc strings can be configured in I‑strings, V‑strings or tension strings depending on the line design.

4.2 Anti‑pollution and aerodynamic profiles

To improve performance in polluted or sandy environments, manufacturers offer several profile variants:

Standard glass insulators: suitable for low pollution levels and standard atmospheric conditions.

Anti‑pollution glass insulators: longer creepage distance, larger sheds and optimized profiles designed to resist salt fog, industrial smoke and coastal contamination.

Aerodynamic glass insulators: streamlined shed shapes for arid and sandy zones to minimize dust and sand accumulation and promote self‑cleaning.

Advanced solutions may add RTV silicone coatings to the glass surface to impart hydrophobicity, further improving performance in very high contamination environments.

4.3 Glass vs porcelain and composite

Compared with high‑voltage porcelain insulators and composite insulators, glass power line insulators offer:

Excellent visual inspectability due to their transparency.

Very stable long‑term electrical properties with limited aging.

Self‑destruction capability that prevents undetected puncture.

Porcelain insulators remain widely used, especially for post insulator transmission line and station applications, while polymer/composite insulators offer weight and contamination advantages in some cases. Selection depends on system design, standards and environmental constraints.

5. Electrical performance in clean and polluted environments

5.1 Clean environment performance

In clean environments, the main electrical parameters for glass suspension insulators are:

Dry and wet power‑frequency withstand voltage.

Lightning impulse withstand and flashover voltage.

Switching impulse performance (for EHV/UHV).

These parameters are determined according to standards such as IEC 60383, IEC 60433, IEC 60060 and IEC 60071‑1 and must exceed the system’s insulation coordination requirements.

5.2 Pollution effects

In polluted environments, airborne salt, dust, industrial pollutants and other contaminants can deposit on the surface of the glass insulator. When this pollution layer becomes wet due to fog, dew, rain or condensation, its surface conductivity increases, causing higher leakage current and local heating.

This process can create dry bands along the creepage path, where arcs form and extend, eventually leading to complete flashover if not controlled. Because of this, the specific creepage distance (mm/kV) and shed geometry are essential design parameters for glass electrical insulators in polluted environments.

Utilities classify pollution severity (e.g., light, medium, heavy, very heavy) and select anti‑pollution glass insulators accordingly, often guided by IEC standards and CIGRÉ recommendations.

6. Flashover and withstand voltage tests

6.1 Withstand tests

Withstand voltage tests verify that an insulator or string can endure specified voltages without breakdown during a defined test time. Typical tests include:

Power‑frequency dry and wet withstand.

Lightning impulse withstand (positive and negative).

Switching impulse withstand for EHV/UHV applications.

These tests are performed in high‑voltage laboratories with standardized waveforms, clearances and background conditions according to IEC or ANSI requirements.

6.2 Flashover tests

Flashover tests identify the voltage at which a continuous arc forms between the energized conductor and the grounded end across the insulator surface. In pollution testing, artificial pollution layers are applied to glass power line insulators and wetted, then power‑frequency voltage is raised until flashover occurs.

By repeating tests on insulators with different profiles and creepage distances, engineers can compare flashover strengths and determine the most robust designs for a particular environment. The study you referenced shows that disc profile has a strong impact on flashover voltage under pollution.

7. Finite element analysis (FEA) of glass insulators

Finite element analysis is a powerful tool used to simulate electric field and potential distribution around glass insulators on power lines. In performance analysis of high‑voltage disc insulators with different profiles, FEA complements laboratory flashover and withstand tests.

Key engineering insights from FEA include:

Potential distribution along the insulator string, showing how many discs share the voltage stress.

Local electric field peaks at triple junctions (metal–glass–air or pollution–glass–air) that often correlate with partial discharges and arc inception.

The influence of pollution layer conductivity and thickness on surface electric field and leakage current paths.

By adjusting the insulator profile (e.g., alternating sheds, aerodynamic shapes) and simulating various pollution conditions, designers can minimize field peaks and maximize flashover strength before prototypes are built. This reduces design iterations, shortens time to market, and supports compliance with insulation coordination requirements.

8. Key selection criteria for glass electric insulators

When specifying glass power line insulators for a transmission or distribution project, engineers must consider:

Line voltage and insulation level (BIL, SIL).

Required mechanical strength (e.g., 70 kN, 120 kN, 160 kN, 300 kN).

Environmental conditions: pollution severity, altitude, temperature range, UV exposure, wind and icing.

Required creepage distance and disc profile type (standard, anti‑pollution, aerodynamic).

Applicable standards and system codes (IEC, ANSI, national standards).

Maintenance philosophy (live‑line washing, periodic inspections, replacement strategy).

Manufacturers usually publish detailed catalogues with model‑specific parameters such as mechanical failing load, disc diameter, shed spacing, creepage distance, dry and wet withstand voltages and impulse ratings. For complex or unique applications, they may also provide customized FEA studies and pollution tests.

9. “What to do with glass insulators” – utility and safety perspective

In a professional electrical context, glass insulators are not treated as decorative collectibles but as engineered safety components. For utilities and industrial owners, the correct handling approach is:

Keep compliant, undamaged glass suspension insulators in service as long as they meet inspection and testing requirements.

Remove cracked, shattered or severely polluted insulators during routine or emergency maintenance and replace them with certified units.

Dispose of damaged glass electric insulators as industrial waste following local environmental and safety regulations.

Refrain from re‑using old or unknown‑origin insulators on power lines, as this may violate standards and create safety risks.

10. Design and testing standards relevant to insulators

When specifying or purchasing glass power line insulators, engineers must consider relevant international and national standards:

•IEC 60383 and IEC 60433: for disc and string insulators used on AC overhead lines.

•IEC 60060 and IEC 60071 1: high voltage testing techniques and insulation coordination.

•IEC 60168: tests on indoor and outdoor post insulators of ceramic or glass.

•IEC 60437 and related standards: radio interference and other special tests.

These standards define test voltages, pollution tests, mechanical failing loads, type tests, routine tests and acceptance criteria for insulator transmission line components. Compliance ensures interchangeability, safety and long term reliability across different networks and manufacturers.

For external authority references, links such as IEC (International Electrotechnical Commission) and IEEE (Institute of Electrical and Electronics Engineers) standards repositories, as well as general overviews like the “Insulator (electricity)” article on Wikipedia, can be cited in supporting documentation.

11. Glass insulators value for modern grids

From a system perspective, the value of glass electric insulators lies in their ability to improve reliability, reduce maintenance and extend asset life.

Key benefits include:

Long service life (often 30+ years) with stable electrical performance and limited aging.

Visual inspection without complex diagnostic tools, as defects in glass are easy to see.

High mechanical and thermal robustness for extreme climate conditions.

Optimized profiles and anti‑pollution designs for harsh environments, especially when supported by FEA and laboratory flashover testing.

When these factors are integrated into project design, glass power line insulators contribute significantly to lower outage rates and total life‑cycle costs.

12.FAQ

Question1: What are glass insulators used for on power lines?

Answer1: Glass power line insulators are used to mechanically support high-voltage conductors and electrically insulate them from towers or poles. They prevent current leakage, flashovers and short circuits, ensuring safe and reliable transmission of electricity.

Question2: What should utilities do with old or damaged glass insulators?

Answer2: Old or damaged glass electrical insulators should be removed from service, replaced with certified units and disposed of according to local regulations. They must not be reused on live lines unless they are fully tested and compliant with current standards.

Question3: What factors matter when selecting high-voltage glass insulators?

Answer3: Key factors include line voltage and insulation level, mechanical strength requirements, local pollution and climate, the required creepage distance and insulator profile, applicable IEC or ANSI standards, and the owner's maintenance strategy.

High‑voltage glass electrical insulators engineered to IEC 60383 and IEC 60433 provide long service life in coastal, industrial and desert environments, with tensile strengths up to 300 kN and voltage ratings up to 1000 kV.

If you are planning a new insulator transmission line project or upgrading existing lines in polluted areas, contact our engineering team for optimized glass suspension insulator designs, FEA support and complete type test documentation

Contact us for more info and request a technical consultation.