-

Home > News > Industry News

Why Glass Insulators Are Still Preferred in Modern Power Grid Projects

Why Glass Insulators Are Still Preferred in Modern Power Grid Projects

1.Why Glass Insulators Still Matter in Modern Power Grids

In modern power grid projects, utilities can choose among several types of power line insulators: porcelain, polymer/composite, and glass insulators. Yet for many high‑voltage transmission and critical distribution lines, glass electrical insulators are still preferred because they combine high dielectric strength, long service life, excellent visibility of defects, and stable performance in harsh outdoor environments.

As transmission voltages rise toward extra‑high voltage (EHV) and ultra‑high voltage (UHV) levels, the demands on power line insulators increase dramatically. High voltage glass insulators are engineered specifically to withstand strong electric fields, heavy mechanical loads from long spans and conductor weight, as well as pollution, ice, wind and UV exposure over decades of continuous operation.

For engineers and project owners, the key question is no longer “is glass an insulator?” but “why are glass insulators still the most robust, cost‑effective insulators on power lines in many modern grid applications?” This article explains the reasons from a technical, economic and operational perspective.

2. What Is a Glass Insulator? Glass Conductor or Insulator?

2.1 Is Glass an Insulator or a Conductor?

From an electrical engineering perspective, glass is a classic example of a solid dielectric material. In other words, glass is an insulator, not a conductor.

The volume resistivity of glass is extremely high, so almost no current flows through it under normal operating voltage.

Glass shows high dielectric strength, meaning it can withstand intense electric fields without internal breakdown.

Its smooth surface helps limit surface leakage current and arc formation when properly designed.

Therefore, whenever we talk about a glass electrical insulator, we are talking about using glass as an insulator, not as a conductive element. Phrased another way: glass insulator or conductor? Glass is very clearly an insulator and is used exactly because it is a reliable barrier against high voltage.

2.2 What Is a Glass Insulator in Power Systems?

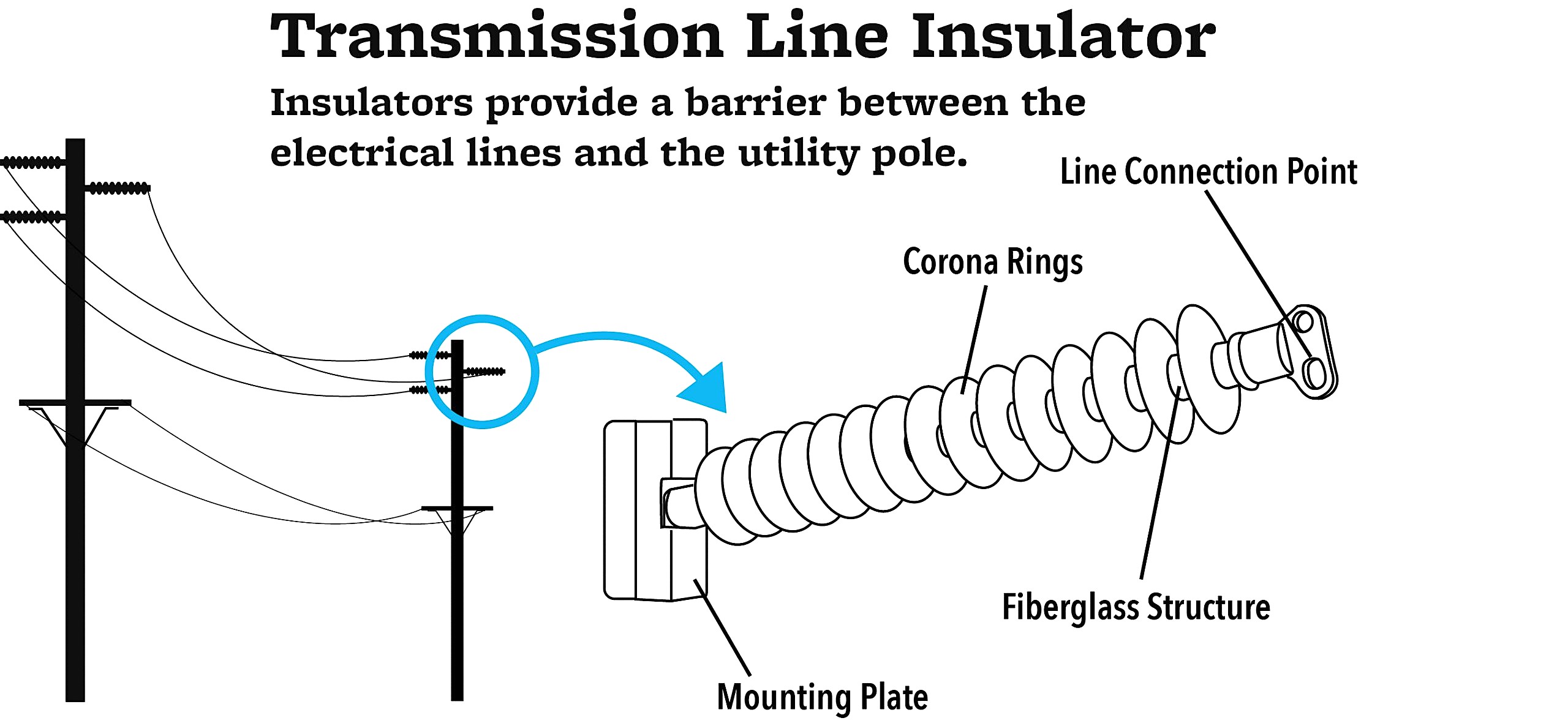

In power engineering, a glass electrical insulator is a device made from toughened (tempered) glass, combined with metallic hardware, used to:

Provide high voltage insulation between live conductors and grounded structures (towers, poles, substation frames).

Provide mechanical support and withstand tension, compression and bending from conductors, wind, ice and their own weight.

Typical constructions include:

A glass body (often borosilicate or specially formulated tempered glass) providing the insulating path.

Steel caps and forged steel pins or ball‑socket fittings providing mechanical attachment to conductors and crossarms.

Because glass is an insulator with very high dielectric strength, the glass body blocks current flow while the metallic fittings transfer mechanical forces.

2.3 What Are Glass Insulators Used For?

In today’s grids, glass insulators are widely used in:

Overhead high‑voltage transmission lines (typically 35 kV up to 1000 kV).

High‑voltage distribution lines where reliability and visual inspection are critical.

Power line crossings over rivers, highways and railways, where failure risk must be minimized.

Substations, as glass post or disc units supporting busbars and equipment in some designs.

So when we ask what are glass insulators, the precise answer is: they are electric glass insulators used to insulate and mechanically support conductors in overhead lines and substations, particularly at medium, high and extra‑high voltage levels.

3. Different Types of Power Line Insulators

The phrase Different Types of Power Line Insulators typically includes three major material families and several shape categories. Understanding these helps explain why glass insulators for power lines are often favored in specific projects.

3.1 By Material: Glass, Porcelain, Polymer/Composite

Glass Insulators

Toughened glass discs or shells.

High dielectric strength, excellent surface cleanliness, self‑shattering (zero‑value) fault indication.

Porcelain Insulators

Based on alumina‑silicate ceramics with glazed surfaces.

Long historical use, good compressive strength, but defects are difficult to see and aging in pollution can be an issue.

Polymer/Composite Insulators

Fiberglass core with silicone rubber or polymer housing.

Lightweight and good hydrophobicity, but long‑term ageing and tracking under UV and pollution need careful management.

3.2 By Shape and Function

Among the different types of power line insulators, the shapes below are common across materials, including glass insulators:

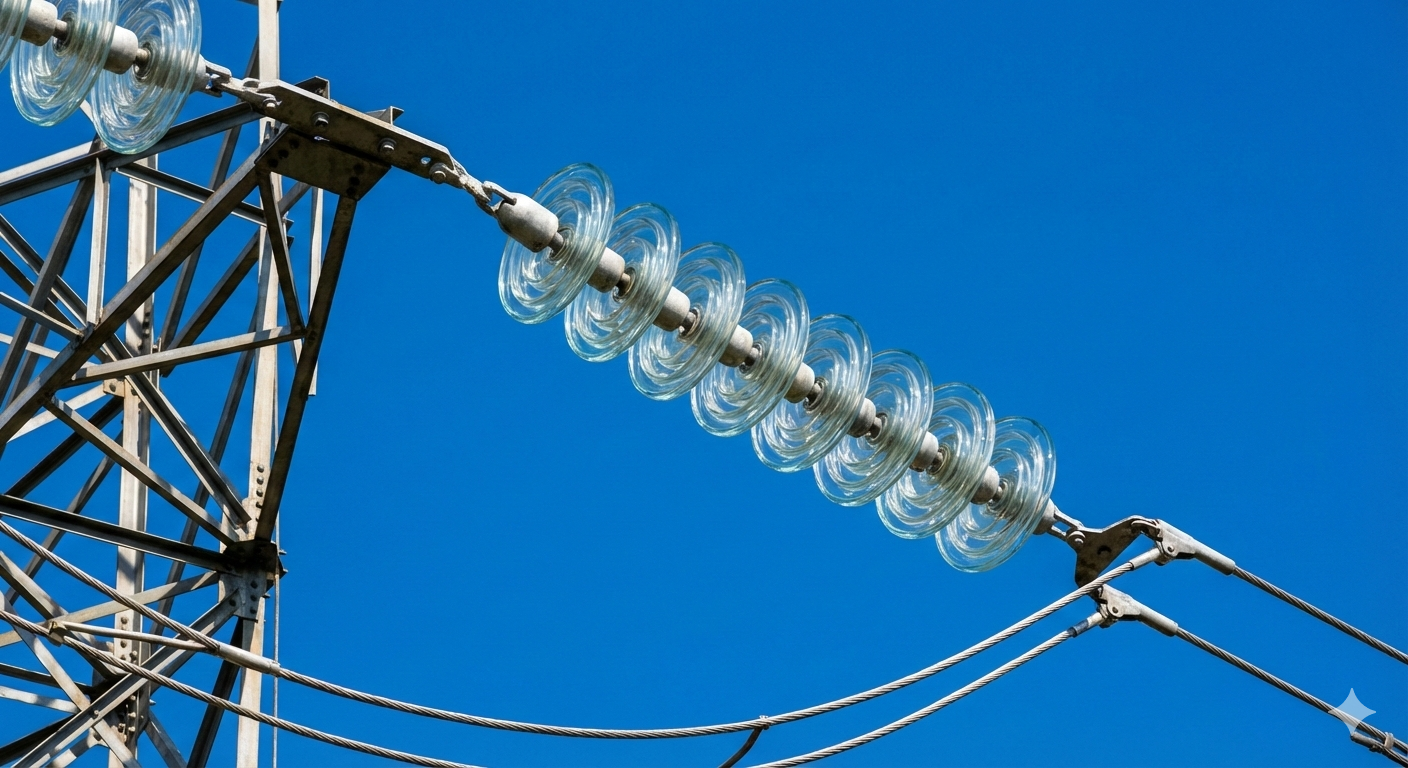

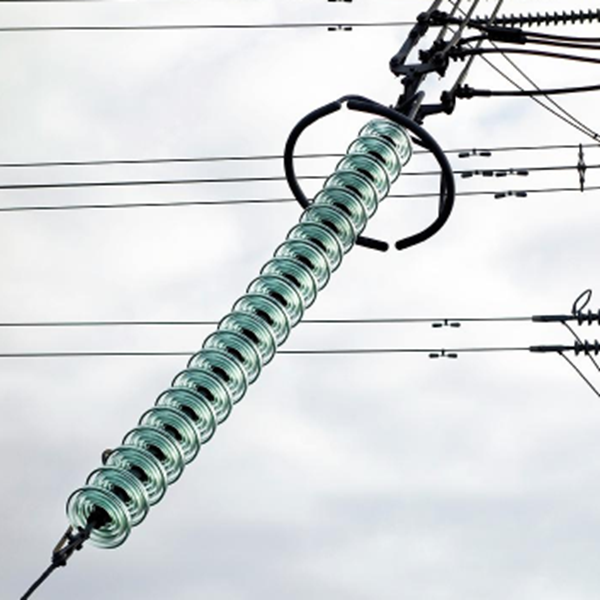

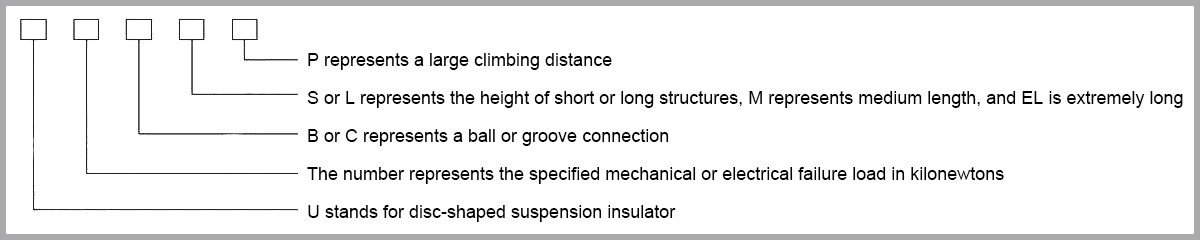

Suspension (Disc) Insulators

A string of glass discs forms a high voltage glass insulator chain.

Each disc has a standard mechanical and electrical rating; project voltage is achieved by adjusting the number of discs.

Tension (Strain) Insulators

Similar to suspension but used at dead‑ends or angle towers to handle high tensile loads.

Post Insulators

Rigid units used mainly in substations or on poles for medium‑voltage lines.

Line Spacers and Special Units

For bundled conductors, crossings, or areas with specific aerodynamic or pollution conditions.

Within glass insulators specifically, you also see profile variants such as standard type, fog type, aerodynamic type and double‑umbrella type, optimized for different pollution and climate conditions.

4. Why Glass as Insulator: Material and Electrical Advantages

4.1 Superior High Voltage Insulation

One of the main reasons glass insulators are still preferred in modern power grid projects is their high dielectric strength and stable high voltage insulation performance.

High dielectric strength allows glass electrical insulators to withstand large electric field stresses in EHV and UHV lines without internal breakdown.

The smooth glass surface provides a long creepage path with low surface roughness, which helps control leakage current and delay the onset of flashover under wet or polluted conditions.

For an insulator for high voltage applications, this combination of high bulk dielectric strength and good surface behavior is essential. High voltage glass insulators can be deployed from tens of kilovolts up to about 1000 kV in AC systems when configured properly.

4.2 Excellent Arc Resistance and Surface Performance

In service, powerline insulators are regularly exposed to switching surges and lightning impulses. Glass as insulator offers:

High arc resistance: glass does not easily carbonize, so it resists permanent tracking damage better than some organic materials.

Self‑cleaning tendency: the hard, hydrophilic surface allows rain and wind to wash away part of the contamination layer, particularly when combined with optimized ribs and sheds.

Profile designs such as fog type, open profile and aerodynamic ribs are used in high voltage glass insulators to ensure reliable surface insulation under heavy rain, salt fog or dust storms.

4.3 Mechanical Strength and Toughened Glass

Modern high voltage glass insulators are made from toughened glass, meaning the surfaces are in compression and the core in tension. This provides:

High mechanical strength to withstand conductor tension, wind load and ice load over long spans.

Good resistance to mechanical shocks from debris, birds or minor impact.

If catastrophic damage occurs, toughened electric glass insulators will shatter into many small pieces and lose almost all mechanical strength (“zero‑value” property). This is a safety advantage because the failure is immediately visible and the insulator is not able to carry load in a partially damaged, dangerous state.

5. Design Features of High Voltage Glass Insulators

5.1 Disc and Cap‑Pin Construction

The classic glass powerline insulator is the disc‑type cap‑and‑pin unit:

The glass shell provides insulation and the creepage path.

A galvanized steel cap and forged steel pin are cemented or mechanically locked to the glass body.

Multiple discs form one insulator string, which can be dimensioned to the required voltage and pollution class.

This modular approach means that a single glass power pole insulators design can be used in many different system voltages simply by changing the number of discs.

5.2 Specialized Profiles for Harsh Environments

Manufacturers offer various profiles of high voltage glass insulators for specific environmental conditions:

Standard Profile: for light or normal pollution.

Fog Profile: longer creepage path and deeper ribs to prevent flashover under heavy rain and fog conditions.

Open Profile: designed to reduce pollution build‑up by improving airflow, effective in desert, icy or dust‑heavy regions.

External Shed / Double Umbrella:improved self‑cleaning performance in heavy industrial or saline environments.

By selecting the correct insulator high voltage profile, utilities can significantly reduce maintenance frequency and improve line reliability.

5.3 Self‑Breaking and Easy Fault Detection

The self‑breaking feature of toughened glass is a decisive advantage over porcelain and some composite designs:

When a glass disc is overstressed electrically or mechanically, it shatters into small pieces and clearly indicates failure.

There is no hidden crack inside an apparently intact insulator; either the disc is healthy, or it is visibly broken and provides zero mechanical strength.

This property simplifies line inspection because crews or drones can visually spot failed glass insulators on power lines from a distance without complex diagnostic equipment.

6. Operational Advantages: Why Glass Insulators Are Still Preferred

6.1 Reliability in High Voltage and UHV Projects

Modern EHV and UHV lines (e.g., 400 kV, 500 kV, 765 kV, 800 kV and beyond) place extreme demands on powerline insulators. Glass electrical insulators have proven:

Reliable performance up to about 1000 kV in AC overhead transmission systems when properly designed.

Low ageing rate: decades of field experience show that glass maintains its electrical and mechanical properties very stably over time.

Resistance to UV radiation and weathering: glass does not significantly degrade under solar ultraviolet exposure.

These strengths make a high voltage glass insulator string a very attractive solution for long distance overhead lines in modern grid expansion projects.

6.2 Performance in Polluted and Coastal Environments

In coastal and heavy industrial regions, insulators on power lines suffer from salt, chemical vapors, dust and soot. Glass insulators for power lines perform particularly well because:

The hard, smooth surface makes it harder for contamination to permanently adhere compared to porous ceramics.

Optimized profiles (fog type, aerodynamic type, open sheds) increase creepage distance and allow better self‑cleaning by rain and wind.

In many climates, glass insulators show lower flashover rates and need less frequent washing than traditional porcelain units, lowering maintenance costs.

This is one of the key reasons glass insulators remain preferred in polluted corridors, coastal lines, and industrial zones.

6.3 Inspection, Maintenance and Lifecycle Cost

Because glass is transparent and because of its self‑breaking behaviour, inspection is both simpler and more reliable:

Defects, internal cracks and inclusions are easily visible.

Broken discs are obvious from the ground, by helicopter or by drone.

There is less need for complex live‑line testing to find hidden defects, compared to porcelain insulators.

For asset managers, this directly reduces:

Routine inspection time and cost.

Outage risk caused by sudden, unexpected insulator failures.

Lifecycle cost of the line, since cleaning and replacement can be planned more efficiently.

When total cost of ownership is calculated over 30–40 years, glass insulators often show better economics than alternatives, even if the initial purchase price is similar.

7. Comparison with Other Power Line Insulators

7.1 Glass vs Porcelain

Porcelain and glass are both traditional power line insulators materials, but they differ in critical aspects:

Glass has higher dielectric strength and very stable long‑term performance.

Glass allows immediate visual detection of damage, while porcelain can develop invisible internal cracks.

Porcelain offers good compressive strength and can be molded into very complex shapes, but is more sensitive to hidden defects, glaze issues and ageing in severe pollution.

Recent industry analyses show that for new high‑voltage transmission projects, glass insulators are frequently preferred because of their self‑cleaning surfaces, easier inspection and cost‑effective lifecycle performance.

7.2 Glass vs Composite/Polymer

Composite insulators have lower weight and strong hydrophobic surfaces, but:

Their long‑term ageing under UV, tracking and erosion requires careful monitoring.

Fault detection is more difficult; damage may not be visible externally.

Replacement intervals can be shorter in some climates, increasing lifecycle costs.

Because of this, many utilities select a mixed strategy: composite units in special spans or for weight‑critical locations, and glass insulators as the main solution for long lines where predictable long‑term performance and inspection simplicity are more valuable.

8. Applications of Glass Insulators on Power Lines

8.1 High Voltage Transmission Lines

The classic application is glass insulators on power lines in high‑voltage transmission corridors:

110–220 kV: standard glass disc strings for regional transmission.

230–400 kV: longer strings, often with fog profile discs in polluted areas.

500–800 kV and above: engineered strings with many discs, sometimes in double or quadruple strings for redundancy and mechanical strength.

In these projects, a set of glass electrical insulators is not just an accessory; it is a core component determining line reliability, outage statistics and maintenance routines.

8.2 High Voltage Distribution and Subtransmission

Glass power pole insulators are also widely used in:

35–69 kV subtransmission lines.

High‑reliability distribution feeders near substations or critical loads.

They may appear as shorter disc strings, post insulators or special glass electric pole insulators designed for compact line configurations.

8.3 Substations and Specialized Installations

Although porcelain post insulators still dominate in many substations, glass units are used in some designs to:

Support high‑voltage busbars.

Provide insulation in disconnect switches and line terminations.

Serve as part of station entry/exit structures for overhead lines.

Offshore wind farms, coastal substations and desert PV plants are additional examples where electric glass insulators and glass insulators for power lines are attractive thanks to their pollution performance and long life.

9. Clarifying Common Questions: Glass Conductor or Insulator, and Glass Phone Insulators

9.1 Glass Is an Insulator or Conductor?

From the standpoint of basic electrical properties, glass is an insulator, not a conductor. It has very high resistivity and is used to prevent current flow. When people search “glass conductor or insulator” or “glass is an insulator or conductor”, the correct answer in power engineering is clear: glass is an insulator, and that is why we design glass electrical insulators and not glass conductors.

9.2 Glass Phone Insulators vs Modern Power Insulators

Historically, glass phone insulators (glass insulators for telegraph and early telephone lines) were small pin‑type units on wooden poles. They used the same basic principle: glass as insulator to keep communication lines isolated from the pole.

Modern glass insulators for power lines are much more advanced:

Toughened glass, not simple soda‑lime as in many early units.

Designed and tested to international standards for mechanical load and high voltage insulation.

Optimized profiles for pollution, ice and aerodynamic performance.

10. FAQ

Q1: Is glass an insulator in electrical power systems?

Yes. In electrical power systems, glass is used as an insulator because it has very high resistivity and strong dielectric strength. It prevents current from flowing from high‑voltage conductors to grounded towers or poles, which is essential for system safety and reliability.

Q2: What is a glass insulator and what are glass insulators used for?

A glass insulator is a high‑voltage insulation component made from toughened glass combined with metal fittings. Glass insulators are used on overhead power lines and in substations to support conductors mechanically while providing high voltage insulation against the grounded support structures.

Q3: Why are high voltage glass insulators still preferred in modern power grid projects?

High voltage glass insulators are still preferred because they combine strong high voltage insulation, excellent mechanical strength, very stable long‑term performance, good pollution resistance, and easy visual fault detection. These properties deliver high reliability and low lifecycle cost compared with many alternative insulator technologies.

Q4: What are the different types of power line insulators?

Different types of power line insulators include glass insulators, porcelain insulators, and composite (polymer) insulators. By shape, there are suspension (disc) insulators, tension/strain insulators, post insulators and special profile types such as fog, aerodynamic and double‑umbrella designs for different environmental conditions.

Q5: Are glass insulators suitable for polluted or coastal environments?

Yes. Glass insulators are well‑suited for polluted and coastal environments because their smooth, hard surface and optimized profiles help reduce contamination build‑up and support self‑cleaning. In many regions, glass insulators show lower flashover rates and require less washing than porcelain alternatives, making them a preferred choice on coastal and industrial lines.

If your next transmission or subtransmission project requires proven high voltage insulation with low lifecycle cost, consider specifying toughened glass insulators as your primary solution. Our engineering team can help you select the correct profile and string length for your environment and voltage level.