-

Home > News > Industry News

Comprehensive Guide to Glass Suspension Insulators in Power Transmission Introduction to Glass Suspension Insulators

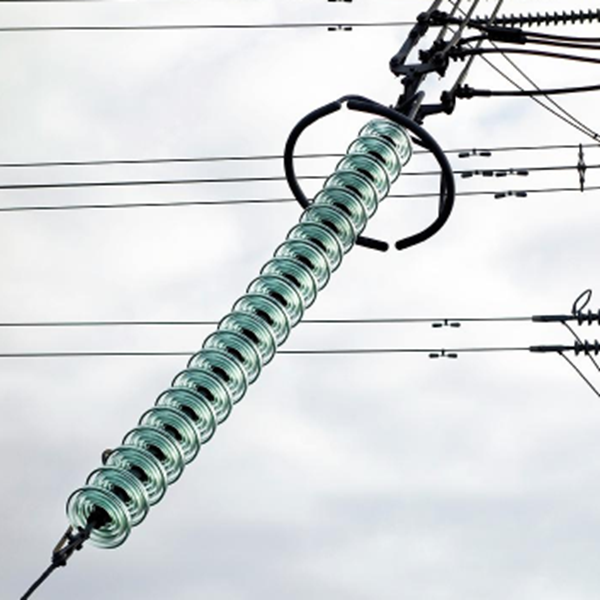

Glass suspension insulators are critical components used in high-voltage power transmission and distribution to support overhead conductors and electrically isolate them from transmission towers. They are made of toughened glass, which ensures superior mechanical strength, electrical insulation, and durability under harsh environmental conditions. The visual detectability of damage, such as breakage, allows for easier maintenance and reduces risks of failure. These insulators conform to recognized industry standards, including ANSI C29.2B, making them trusted worldwide in utility and industrial power applications.

Advantages of Glass Suspension Insulators:

High Dielectric Strength: Toughened glass provides excellent electrical insulation to isolate energized lines efficiently, preventing leakage currents and flashover events.

Mechanical Strength: Glass insulators withstand mechanical stresses from wind, ice loading, and conductor tension with typical tensile strengths ranging from 70 kN (approximately 15,000 lbs) up to 160 kN or higher for heavy-duty applications.

Visual Damage Detectability: Cracked or shattered glass is immediately visible, facilitating quicker safety inspections and maintenance interventions.

Radio Interference Voltage (RIV) Minimization: Glass suppresses RIV effectively, preventing interference with nearby communication systems unlike some porcelain insulators.

Long Service Life: Resistance to aging, chemical attack, and thermal cycling leads to a long operational lifetime, reducing replacement frequency.

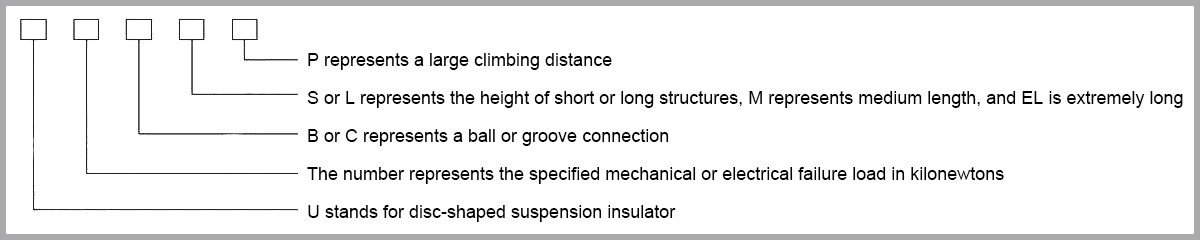

Technical Specifications and Standards

Glass suspension insulators typically feature the following key specifications:

Mechanical and electrical strength ratings range from about 15,000 lbs to over 35,000 lbs (70 kN to 160 kN).

Creepage and leakage distances (the effective length of the insulator surface path that prevents current flow) typically measure around 320 mm (12.6 in) or more, depending on voltage class and profile design.

Flashover voltages in dry conditions range around 80 kV, while wet conditions reduce to about 50 kV, with critical impulse flashover voltages reaching 125 kV or higher.

Fittings are commonly made from galvanized steel to resist corrosion, with standardized designs like the ball-and-socket or clevis connections facilitating installation and interchangeability.

Insulators comply with ANSI C29.2B, IEC 60383, and other relevant international standards ensuring uniformity and reliability.

Profile Types and Pollution Performance

Several shed profiles are designed to optimize performance under different environmental conditions:

Standard Profile: Features well-spaced under-ribs beneficial in light to medium pollution areas, with a leakage distance to spacing ratio of about 2.2.

Fog Type Profile: Has longer, widely spaced sheds to avoid arc bridging in coastal or salt fog environments, increasing the creepage distance ratio (~3.2).

Open Profile: Eliminates under-ribs to reduce pollution accumulation, ideal for dry desert regions with infrequent rain. Also used to mitigate ice-bridging.

External Shed and Spherical Profiles: Designed for extreme pollution with self-cleaning properties, reducing manual cleaning requirements.

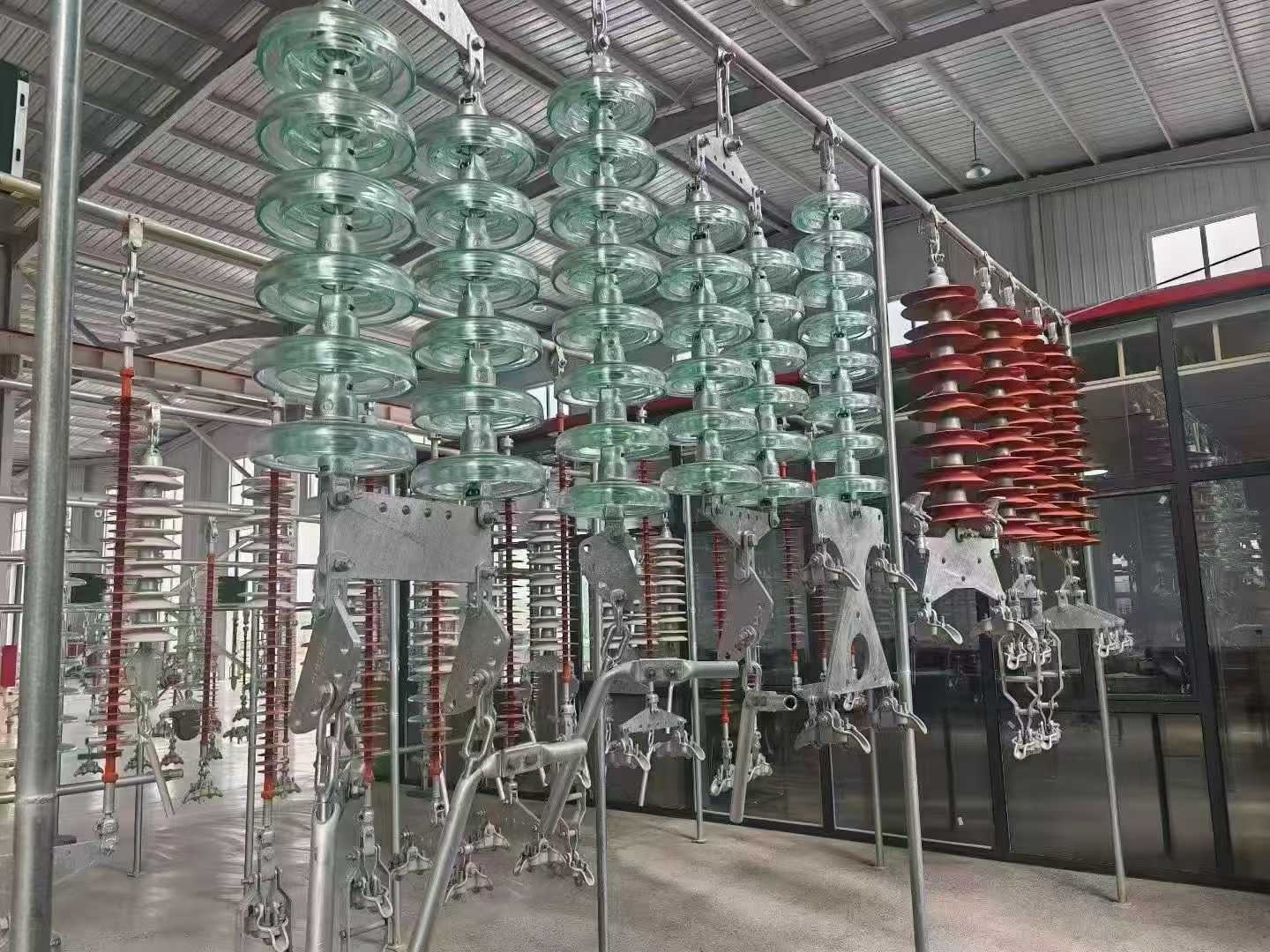

Applications of Glass Suspension Insulators

They find wide application in:

High-voltage overhead transmission lines, providing mechanical support and electrical insulation.

River crossings or extreme terrain requiring high mechanical strength and reliability.

Industrial power distribution where long service life and resistance to environmental factors are demanded.

Railway electrification, substations, and corrosion-prone coastal regions requiring specialized profiles and materials.

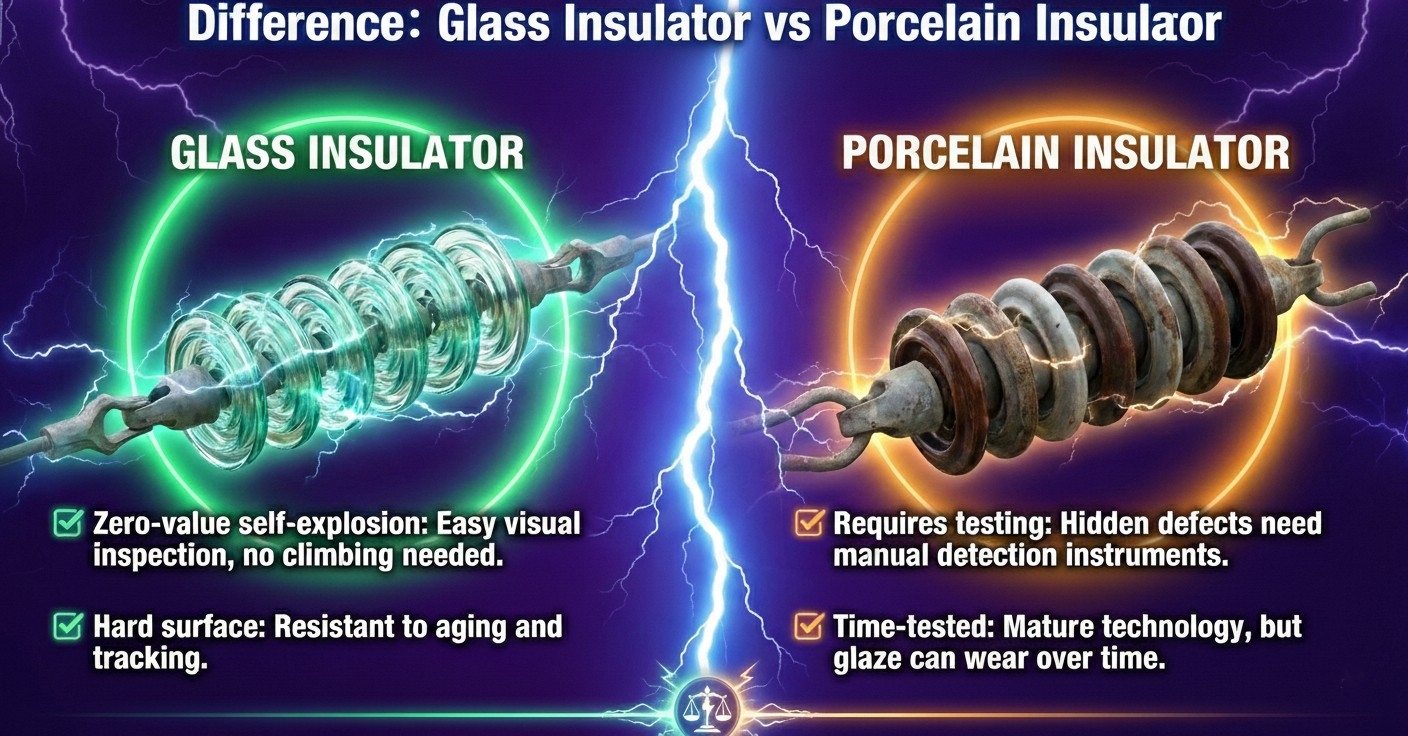

Comparison with Other Suspension Insulators

| Feature | Glass Suspension Insulators | Porcelain Suspension Insulators | Composite/Polymer Suspension Insulators |

|---|---|---|---|

| Mechanical Strength | High (70 kN to 160 kN typical) | Very High (up to 400 kN in some cases) | High but generally lower than porcelain/glass |

| Electrical Insulation | Excellent dielectric strength & visibility | Excellent dielectric properties | Hydrophobic surfaces for pollution resistance |

| Weight | Moderate | Heavier | Lightweight |

| Maintenance | Easier (damage visible) | Requires inspection, less visible damage | Low maintenance, resistant to contamination |

| Pollution Resistance | Good (with appropriate profile) | Good | Superior, ideal for heavily polluted areas |

| Cost | Competitive | Generally lower cost | Higher initial cost but potentially lower lifetime cost |

| Susceptibility to Damage | Brittle but shatters visibly | Brittle, risk of undetected micro-cracks | Less brittle, more flexible |

Glass suspension insulators strike a strong balance between reliability, ease of maintenance, and cost, while composites offer advanced pollution resistance and porcelain offers very high mechanical strength at heavier weights.

Installation and Maintenance Best Practices

Installation involves securely fitting the galvanized steel metal ends into the tower and conductor hardware using standardized ball-and-socket or clevis joints. Because glass insulators show visible damage such as cracks or breaks easily, routine visual inspections can prevent sudden failures. Maintenance is generally minimal but important for environments prone to high pollution or mechanical wear, where regular cleaning or profile selection is crucial to long-term performance.

Upgrade your power transmission infrastructure with our premium glass suspension insulators, combining superior durability, mechanical strength, and electrical reliability.Designed for easy installation and maintenance, our insulators provide long-term performance in diverse environments at competitive suspension insulator prices. Contact us today to enhance the safety and efficiency of your energy transmission systems.