-

Home > News > Industry News

Glass Electrical Insulators: Complete Guide to Types, Performance & Applications

Glass Electrical Insulators: Complete Guide to Types, Performance & Applications

Introduction to Glass Electrical Insulators

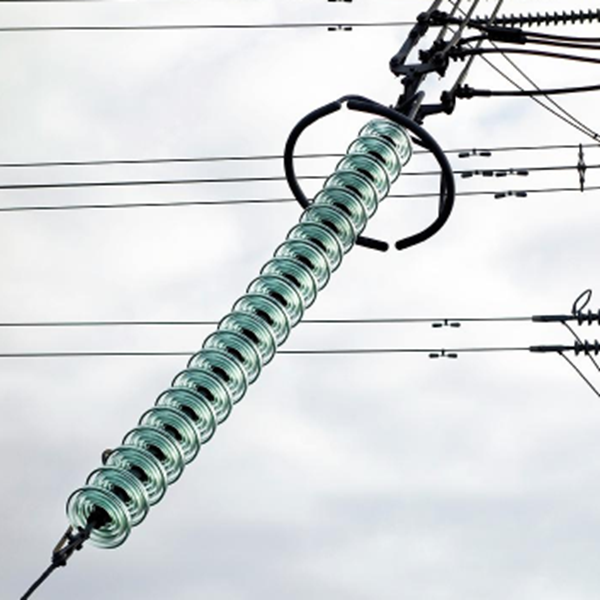

Glass electrical insulators are essential components in modern power transmission and distribution systems. Designed to prevent electrical currents from straying from their intended path, they ensure the safe and efficient delivery of electricity to homes, businesses, and industries. Despite their small size, these insulators play a critical role in protecting power lines, equipment, and personnel from electrical hazards.

For over 180 years, glass insulators have evolved from simple telegraph line devices to highly engineered solutions used in high-voltage networks worldwide.

What Is a Glass Electrical Insulator?

A glass electrical insulator is a specially designed component made of tempered glass that prevents the flow of electricity to unwanted areas, such as poles or towers. Unlike metal conductors, glass insulators resist electrical currents while providing mechanical support for power lines.

Glass insulators are widely recognized for their transparency, durability, and resistance to environmental conditions like rain, dust, and pollution.

Raw Material Composition and Manufacturing Process

Glass insulators are primarily made from silica (SiO₂), along with other additives to enhance mechanical and electrical properties. The manufacturing process typically involves:

- Melting Raw Materials: Silica, soda, and lime are melted in a furnace at high temperatures.

- Molding and Forming: Molten glass is poured into precision molds to create the desired insulator shape.

- Annealing: The molded glass is slowly cooled to relieve internal stresses, improving strength and durability.

- Inspection: Each insulator undergoes rigorous electrical and mechanical testing to meet international standards.

Types of Glass Electrical Insulators

Glass insulators are categorized based on their design and application:

- Pin Type Insulators: Used on low- and medium-voltage lines; mounted on poles.

- Suspension Insulators: Suitable for high-voltage transmission lines; hang from towers.

- Strain Insulators: Installed where lines experience mechanical tension, such as at line terminations.

- Shackle and Spool Insulators: Common in telecommunication and light power lines.

Electrical Properties and Performance Standards

Glass insulators are designed to meet strict electrical standards, including:

- Dielectric Strength: Ability to resist high-voltage breakdown.

- Creepage Distance: Surface distance preventing leakage current in polluted environments.

- Mechanical Load Capacity: Strength to withstand wind, ice, and conductor tension.

International standards such as IEC 60383 and ANSI C29 define testing methods and performance requirements for high-voltage glass insulators.

Advantages of Glass Insulators

- High Transparency: Easy visual inspection for cracks and contamination.

- Excellent Electrical Performance: Superior dielectric strength compared to many other materials.

- Durability: Resistant to weathering, UV radiation, and chemical corrosion.

- Long Service Life: Often exceeding 50 years under normal operating conditions.

Disadvantages and Limitations

- Brittle nature makes them prone to shattering under extreme mechanical stress.

- Heavier than some polymer alternatives, affecting installation logistics.

- Limited color and design options compared to composite insulators.

Glass Insulators vs. Porcelain Insulators

Feature | Glass Insulators | Porcelain Insulators |

Electrical Strength | High | High |

Durability | Long-lasting, easy to inspect | Long-lasting, harder to inspect |

Weight | Moderate | Heavy |

Environmental Resistance | Excellent | Good, may require glaze for pollution |

Cost | Slightly higher | Slightly lower |

Applications in Modern Power Systems

Glass insulators are used across a range of electrical infrastructure:

- High-Voltage Transmission Lines: Suspension insulators support heavy conductors.

- Distribution Networks: Pin insulators provide cost-effective insulation.

- Telecommunication Lines: Shackle and spool types for low-voltage lines.

- Railways and Industrial Sites: Specialized designs for mechanical and electrical safety.

Installation, Maintenance, and Safety Considerations

Proper installation and maintenance are critical for ensuring reliability:

- Inspect for cracks, chips, or contamination regularly.

- Avoid over-tightening hardware to prevent mechanical damage.

- Clean surfaces in polluted environments to maintain dielectric performance.

- Follow national electrical codes and safety standards during installation.

Historical Development and Evolution

Glass insulators were first used on telegraph lines in the 1840s. Over time, innovations improved their mechanical strength, electrical performance, and environmental resistance. Today, modern glass insulators combine traditional materials with advanced manufacturing techniques to meet the demands of high-voltage networks.

Frequently Asked Questions (FAQ)

Q1: How can you identify a glass electrical insulator?

A: Look for transparency, smooth surface, and markings indicating voltage and manufacturer.

Q2: Are glass insulators better than porcelain?

A: Glass offers better visibility for inspection and slightly higher electrical performance, but porcelain is mechanically stronger in some cases.

Q3: What is the lifespan of a glass insulator?

A: Typically 50+ years under proper conditions.

Glass electrical insulators remain a cornerstone of reliable power transmission and distribution. With ongoing advancements in material science and design, they continue to provide safe, efficient, and sustainable solutions for modern electrical grids.