Glass Suspension Insulators: Performance Trends in Modern Power Transmission

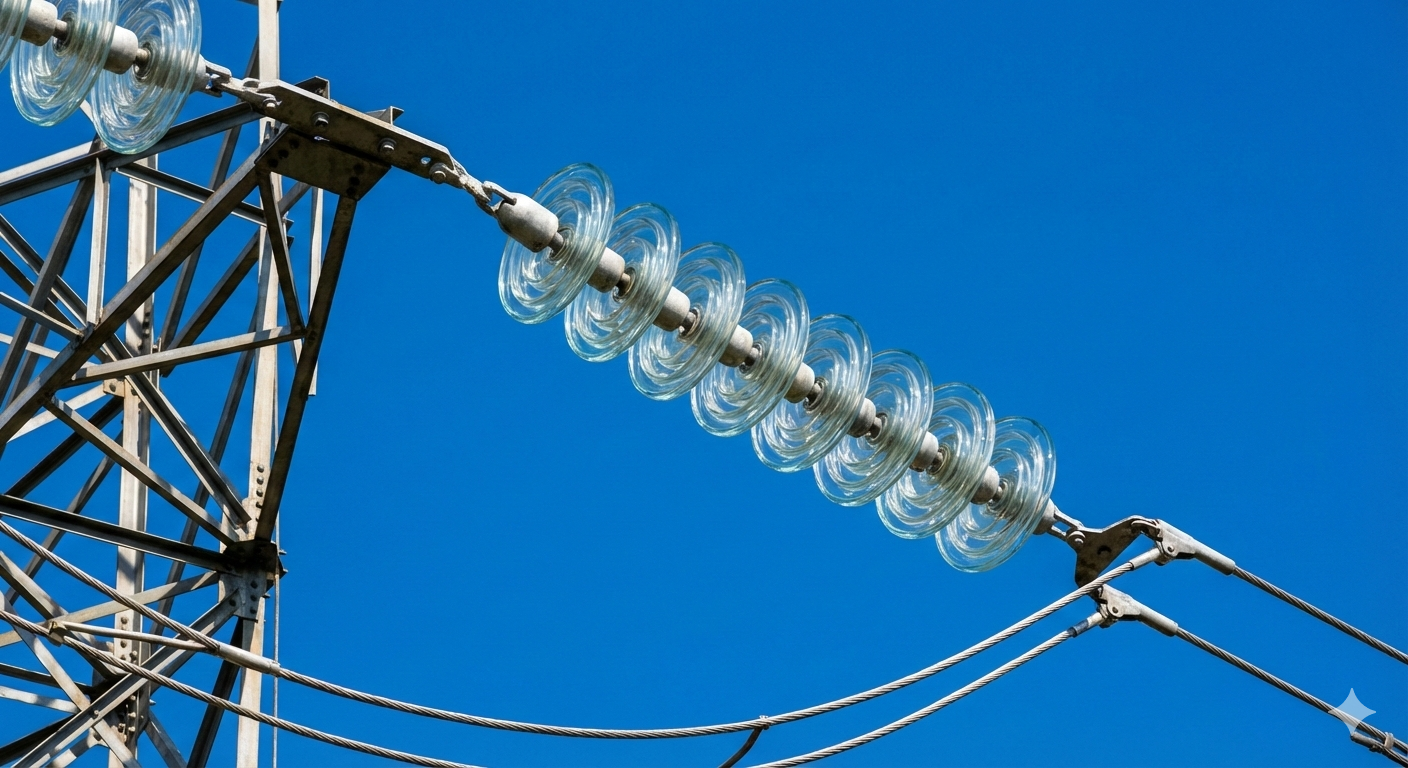

With the continuous expansion of high-voltage and ultra-high-voltage power grids worldwide, glass suspension insulators remain a key component in overhead transmission systems.

Utilities and EPC contractors increasingly favor glass insulators for their stable electrical performance, mechanical reliability, and clear maintenance advantages.

Why Glass Suspension Insulators Remain Widely Used

Glass suspension insulators are manufactured from toughened glass, offering high dielectric strength and consistent electrical insulation under severe operating conditions.

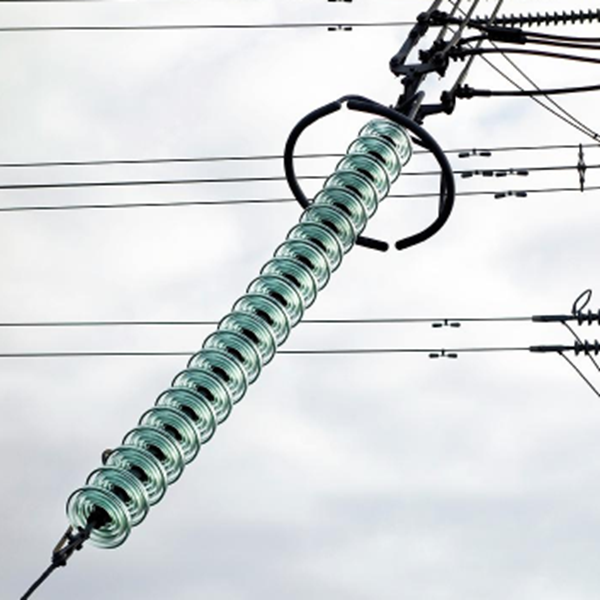

Compared with other materials, glass provides immediate visual indication of damage, allowing utilities to quickly identify failed units and reduce the risk of sudden line outages.

Mechanical and Electrical Performance Overview

From an engineering perspective, glass suspension insulators are designed to withstand combined mechanical loads from conductor tension, wind pressure, and ice accumulation. Typical tensile strength ratings range from 70 kN to 160 kN, making them suitable for standard transmission lines as well as long-span river crossings.

Electrically, these insulators provide reliable insulation performance, with dry flashover voltages around 80 kV and wet flashover voltages near 50 kV. Impulse flashover values can exceed 125 kV, ensuring safety margins during lightning events.

Standards and Global Acceptance

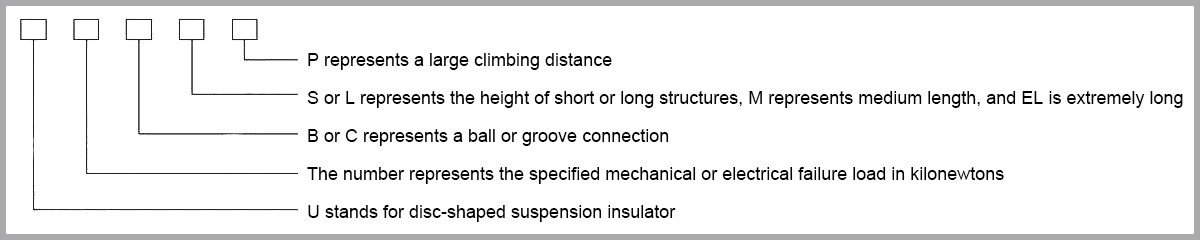

Glass suspension insulators used in modern transmission projects are typically tested and certified according to international standards such as

ANSI C29.2B and IEC 60383.

Compliance with these standards ensures interchangeability, mechanical reliability, and long-term operational safety across different regional power grids.

Profile Design and Pollution Performance

Environmental conditions play a major role in insulator selection. To address this, glass suspension insulators are available in multiple profile designs, each optimized for specific pollution levels and climates.

Standard profiles are commonly applied in light to medium pollution environments.

Fog-type profiles are increasingly used in coastal and high-humidity regions where salt fog and moisture are present.

Open and anti-pollution profiles help reduce contamination buildup in desert or industrial areas with limited natural washing.

Applications Across Power Infrastructure

In today’s power networks, glass suspension insulators are widely applied in:

High-voltage and extra-high-voltage overhead transmission lines

Long-span transmission sections such as river crossings

Industrial and utility power distribution systems

Railway electrification and substation connections

Industry Perspective

While composite insulators continue to gain attention in heavily polluted areas, glass suspension insulators maintain a strong position in the global market. Their balance of cost-effectiveness, mechanical strength, and ease of inspection makes them a preferred choice for many utilities seeking long-term reliability.

As continue worldwide, glass insulators are expected to remain a core solution in power transmission infrastructure, especially where durability, standardization, and lifecycle visibility are critical.